High-grade Forklift Truck Safety Signs for Improved Warehouse Safety

High-grade Forklift Truck Safety Signs for Improved Warehouse Safety

Blog Article

Secret Factors To Consider for Designing Effective Forklift Safety Signs

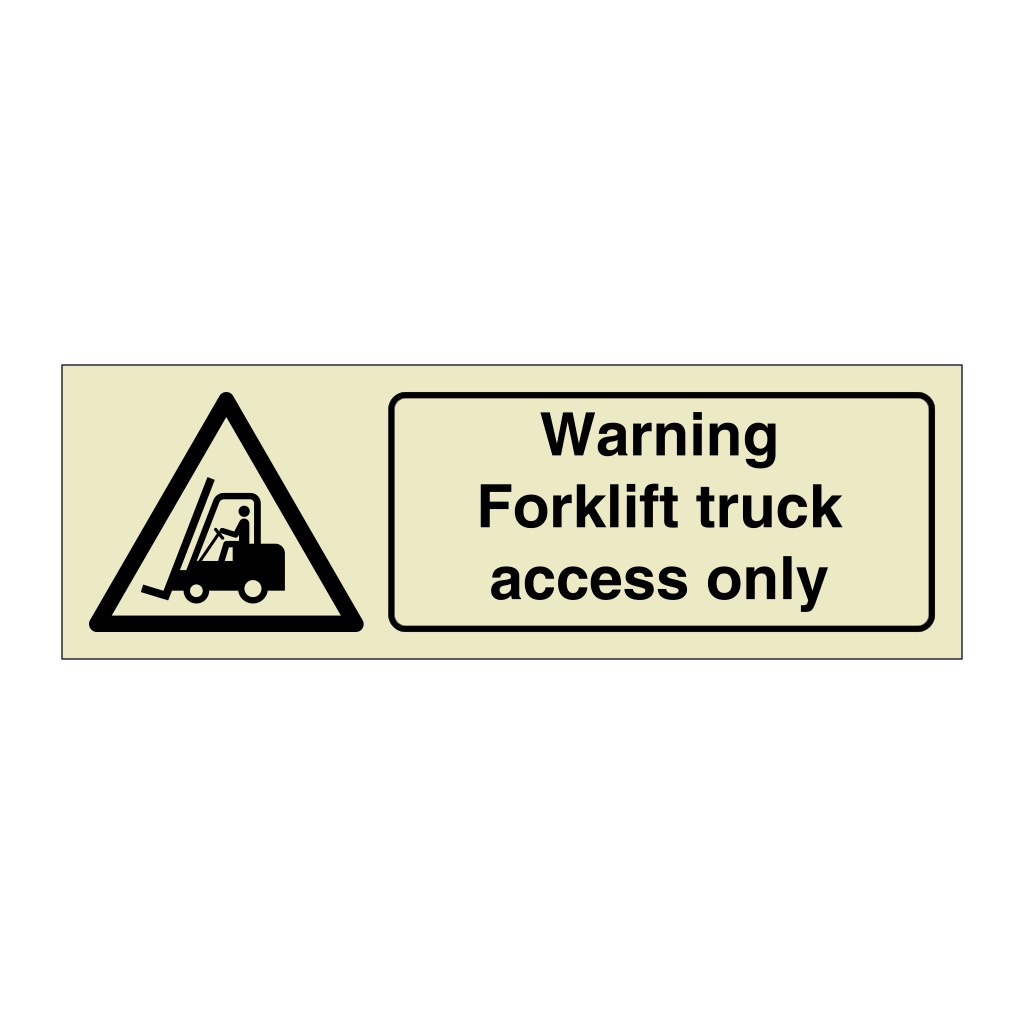

When making reliable forklift safety and security signs, it is vital to consider a number of essential aspects that jointly guarantee ideal presence and quality. Strategic placement at eye degree and the usage of long lasting products like light weight aluminum or polycarbonate further contribute to the durability and effectiveness of these signs.

Shade and Contrast

While designing forklift security indications, the option of color and contrast is vital to ensuring presence and effectiveness. Colors are not simply aesthetic components; they serve important functional objectives by sharing particular messages quickly and reducing the danger of crashes. The Occupational Safety And Security and Health And Wellness Administration (OSHA) and the American National Specification Institute (ANSI) offer standards for utilizing colors in safety and security indications to standardize their definitions. For example, red is generally used to represent instant danger, while yellow signifies warn.

Effective comparison in between the background and the message or signs on the sign is equally crucial. High contrast guarantees that the indication is legible from a distance and in differing illumination conditions. For instance, black text on a yellow background or white message on a red history are combinations that stick out plainly. Additionally, using reflective products can boost visibility in low-light atmospheres, which is usually a consideration in storehouse settings where forklifts run.

Making use of appropriate color and contrast not only sticks to governing criteria however additionally plays an important duty in keeping a safe workplace by ensuring clear communication of risks and instructions.

Font Size and Design

When making forklift safety and security indications, the choice of font style size and design is critical for making sure that the messages are understandable and rapidly comprehended. The main objective is to boost readability, particularly in settings where fast information processing is necessary. The font style size need to be huge sufficient to be reviewed from a range, suiting differing view conditions and making sure that workers can comprehend the sign without unneeded stress.

A sans-serif typeface is normally suggested for safety and security indications because of its clean and straightforward look, which enhances readability. Typefaces such as Arial, Helvetica, or Verdana are commonly chosen as they lack the intricate details that can cover vital details. Consistency in font design across all security signs aids in creating an uniform and specialist look, which even more enhances the importance of the messages being shared.

Additionally, focus can be achieved with critical use of bolding and capitalization. Secret words or expressions can be highlighted to draw immediate interest to essential directions or warnings. Overuse of these methods can result in aesthetic mess, so it is essential to use them deliberately. By thoroughly picking appropriate font style dimensions and styles, forklift security indicators can effectively interact vital safety details to all employees.

Placement and Visibility

Ensuring ideal placement and exposure of forklift safety and security indicators is extremely important in commercial settings. Proper sign positioning can substantially minimize the risk of accidents and boost general work environment safety.

Signs ought to be well-lit or made from reflective products in poorly lit areas to ensure they are visible at all times. By thoroughly taking into consideration these facets, one can ensure that forklift safety signs are both effective and visible, thus fostering a more secure working environment.

Material and Longevity

Selecting the right materials for forklift safety signs is crucial to ensuring their longevity and effectiveness in industrial environments. Offered the rough conditions commonly run into in storehouses and producing facilities, the products chosen should endure a variety of stressors, including temperature variations, dampness, chemical direct exposure, and physical effects. Resilient substrates such as light weight aluminum, high-density polyethylene (HDPE), and polycarbonate are preferred options because of their resistance to these elements.

Light weight aluminum is renowned for its effectiveness and rust resistance, making it an outstanding choice for both interior and exterior applications. HDPE, on the various other hand, uses extraordinary impact resistance and can endure long term exposure to harsh chemicals without weakening. Polycarbonate, recognized for its high effect strength and quality, is typically used where presence and toughness are vital.

Equally crucial is the type of printing utilized on the indicators. UV-resistant inks and protective layers can considerably boost the lifespan of the signs by protecting against fading and wear triggered by long term exposure to sunlight and various other environmental variables. Laminated or screen-printed surfaces supply added layers of protection, making sure that the critical security info continues to be legible gradually.

Buying high-quality materials and durable production processes not only expands the life of forklift safety signs however also strengthens a society of safety go to these guys and security within the office.

Compliance With Regulations

Abiding by regulative requirements is extremely important in the design and deployment of forklift safety indications. Compliance makes sure that the indicators are not just reliable in conveying crucial safety info however likewise satisfy legal responsibilities, consequently alleviating possible responsibilities. Numerous companies, such as the Occupational Security and Health And Wellness Administration (OSHA) in the United States, provide clear guidelines on the specifications of security indicators, including color design, text dimension, and the inclusion of universally recognized symbols.

To follow these regulations, it is necessary to perform a thorough testimonial of suitable requirements. OSHA mandates that safety signs have to be noticeable from a distance and consist of certain colors: red for danger, yellow for care, and eco-friendly for safety guidelines. Furthermore, adhering to the American National Requirement Institute (ANSI) Z535 collection can index better boost the performance of the signs by standardizing the style elements.

Furthermore, regular audits and updates of security indications ought to be see post carried out to make certain continuous conformity with any type of adjustments in policies. Involving with accredited safety professionals throughout the style phase can also be helpful in making certain that all regulatory demands are satisfied, which the indications offer their designated objective properly.

Conclusion

Creating efficient forklift safety and security signs calls for careful interest to shade contrast, font style size, and design to ensure ideal exposure and readability. Adherence to OSHA and ANSI standards systematizes security messages, and incorporating reflective products boosts visibility in low-light circumstances.

Report this page